Channels

We offer a wide range of construction channel which are used in the construction and electrical industries for light structural support, often for supporting wiring, plumbing, or mechanical components such as air conditioning or ventilation systems. These are available in various sizes ranging from 75 mm to 400 mm. These are corrosion resistance, have high tensile strength and are dimensionally accurate. These are made up of high quality raw material procured from our trusted sources.

We are an ISO 9001:2008,ISO 9001-2008, ISO 14001-2004, OHSAS 18001-2007, NSIC-CRISIL, EEPC, and QA-UKAS (ISO 9001-2008), SSI Certified company that follows total Quality Management System. and have been recognized as one of the world’s leading stockists and manufacturer of quality metals for over two decades and are committed to quick responses, unsurpassed quality, competitive pricing, reliable deliveries and an exhaustive inventory.We are a leading exporter of qualitative channels that are manufactured from high-grade steel and material at our vendor's site. Our clients have appreciated channels offered by us owing to excellent operations, customized dimensions, affordable price range and long service life.

Channel Specification

| Type | Channel |

| Standred | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

| Material | 304/L, 304H, 309/S, 310/S, 316/L, 317/L, 321, 347 |

| Size | 30mm*15mm*15mm*1mm-300mm*150mm*150mm*30mm |

| Diameter | 50x37x5mm |

| Order | Accept custom order |

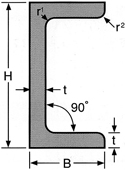

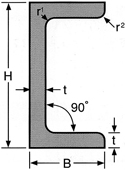

Manufactured dimensions and unit mass

(unit:kg/m)| Side Height(B) (H) | Thickness (t) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 15 | ||

| 40×80 | 5.99 | |||||||||

| 50×100 | 6.20 | 7.65 | 9.02 | |||||||

| 65×130 | 12.0 | |||||||||

| 75×150 | 13.9 | 20.3 | ||||||||

| 100×200 | 27.5 | 30.3 | 36.0 | |||||||

| 125×250 | 34.6 | 38.2 | 45.5 | 55.9 | ||||||

Dimensional tolerances

(unit: mm)| Side Height(B) (H) | SideTolerances | SideDeviation | HeightTolerances | Thickness (t) and thickness tolerances | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 15 | ||||

| 40×80 | ±1.5 | ≦2.0 | ±1.5 | ±0.4 | ||||||||

| 50×100 | ±2.0 | ≦2.0 | ±2.0 | ±0.4 | ±0.4 | ±0.4 | ||||||

| 65×130 | ±2.0 | ≤3.0 | ±2.0 | ±0.5 | ||||||||

| 75×150 | ±2.0 | ≤3.0 | ±2.0 | ±0.5 | ±0.5 | |||||||

| 100×200 | ±3.0 | ≤4.0 | ±3.0 | ±0.5 | ±0.6 | ±0.6 | ||||||

| 125×250 | ±3.7 | ≤4.0 | ±3.7 | ±0.5 | ±0.6 | ±0.6 | ±0.6 | |||||

Shape quality

| Name | Tolerances | ||

|---|---|---|---|

| Edge deviation | 40.50 | 65.75 | 100.125 |

| 2.0 or less | 3.0 or less | 4.0 or less | |

| Squareness | 90°±2° | ||

| Bending | 3mm or less over 1 m,3mm over overall length Overall length (m)/1m or less | ||

| Length | 4000, 6000mm | ||

| Length tolerance | +40 -0mm | ||

Section modulus

Radius of gyration area: I = √l/a

Radius of gyration area: I = √l/aSection modulus: Z = l/e

(a = sectional area)

| Standard sectional dimensions (mm) | Sectional area(cm2) | Location of center of gravity(cm) | Cross-section secondary moment(1) (cm4) | Radius of gyration area(i) (cm) | Section modulus(Z) (cm3) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness Side Height(t) (B) (H) | r1 | r2 | a | Cx | Cy | lx | ly | ix | iy | Zx | Zy |

| 4×50×100 | 6.5 | 3 | 7.823 | 0 | 1.36 | 121.0 | 18.1 | 3.93 | 1.52 | 24.3 | 4.99 |

| 5×40×80 | 4.5 | 3 | 7.548 | 0 | 1.16 | 71.1 | 10.9 | 3.07 | 1.20 | 17.8 | 3.83 |

| 5×50×100 | 6.5 | 3 | 9.643 | 0 | 1.41 | 146.0 | 22.1 | 3.89 | 1.52 | 29.2 | 6.16 |

| 6×50×100 | 6.5 | 4.5 | 11.38 | 0 | 1.43 | 168.0 | 25.3 | 3.85 | 1.49 | 33.7 | 7.09 |

| 6×65×130 | 8.5 | 4 | 15.12 | 0 | 1.80 | 390.0 | 58.9 | 5.08 | 1.97 | 60.0 | 12.5 |

| 6×75×150 | 8.5 | 4 | 17.52 | 0 | 2.05 | 609.0 | 92.3 | 5.90 | 2.30 | 81.2 | 17.0 |

| 9×75×150 | 8.5 | 6 | 25.54 | 0 | 2.16 | 850.0 | 120.0 | 5.77 | 2.25 | 113.0 | 24.0 |

| 10×100×200 | 10.0 | 7 | 38.22 | 0 | 2.81 | 2310.0 | 350.0 | 7.77 | 3.03 | 231.0 | 48.8 |

| 15×125×250 | 10.0 | 7 | 70.5 | 0 | 3.64 | 6539.0 | 1011.1 | 9.62 | 3.78 | 523.0 | 114.1 |