Butt weld Stub End Fittings

Trident Enterprises is one of eminent manufacturers and suppliers of high grade Butt weld Stub End Fittings. Trident Enterprises overseas offers a commendable range of Butt weld Stub End Fittings, for the prestigious client with competitive price. Export packaging is grade towards the protection, handling and transport of Butt weld Stub End Fittings by air or sea freight, as such shares many characteristics with export and transport Butt weld Stub End Fittings packing. Backed by a diligent teen of professional, we are engaged in offering an excellent quality range of Butt weld Stub End Fittings.

Trident Enterprises is an Butt weld Stub End Fittings stockholders and suppliers, delivering to whole of the world. We are an ISO 9001:2008,ISO 9001-2008, ISO 14001-2004, OHSAS 18001-2007, NSIC-CRISIL, EEPC, and QA-UKAS (ISO 9001-2008), SSI Certified company that follows total Quality Management System. and have been recognized as one of the world’s leading stockists and manufacturer of quality metals for over two decades and are committed to quick responses, unsurpassed quality, competitive pricing, reliable deliveries and an exhaustive inventory. Butt weld Stub End Fittings to internationally approved quality standards for application. Butt weld Stub End Fittings have excellent quality to fully satisfy customer's requirement. We can offer high quality electro polish fittings. Butt weld Stub End Fittings are manufactured in accordance with national and international product standards, While we can also produce fittings as per special specification of our customers. In case of custom size fabricate Butt weld Stub End Fittings; the welding is done carried out by qualified personnel.

Butt weld Stub End Fittings Specification

| Type | Stub End Fitting |

| Standard | ANSI B 16.9, ANSI B16.28, MSS SP43, MSS P75, JIS2311, JIS 2312, JIS2313, DIN2605 , GB-12459, GB-T13401 etc. |

| Material | Stainless Steel, Duplex, Super Duplex, Carbon Steel, Alloy Steel, Monel, Inconel, Hastelloy, Tatanium & Special Metals |

| Size | 1/8” to 48” |

| Variation | Long Stub End, Short Stub End, Collar, Lap Joint Stub End |

| Thickness | SCH5S/10S, SCH20/40/80/160, STD/XS/XXS, SGP |

| Order | Accept custom order |

| Quality Assurance | All fittings and flanges are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products. |

| Marking & Packing | Products are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All buttweld fittings are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make custom marking on our products.#Protected by End Caps. |

| Value Added Services |

|

| Test Certificates | Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report |

Carbon Steel: ASTM A234 WPB / A420 WPL3/ A420 WPL6/ MSS-SP-75 WPHY 42/ 46/ 52/ 56/ 60/ 65/ 70 |

Alloy Steel: ASTM A234 WP1/ WP5/ WP9/ WP11/ WP22/ WP91 |

Stainless Steel: ASTM A403 WP 304/ 304L/ 304H/ 316/ 316L/ 317/ 317L/ 321/ 310/ 347/ 904L/2205 Duplex Fittings |

Copper Nickel: CuNi10Fe1Mn, CuNi30Mn1Fe |

Other Materials: Monel, Nickel, Inconel, Hastelloy, Copper, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminium, Zinc, Lead, etc. |

Butt weld Stub End Fittings Dimension

| Nominal Pipe Size | Outside diameter of barrel |

Length (F) | Radius (R) | Diameter (G) | ||

|---|---|---|---|---|---|---|

| Minimum | Maximum | Long Pattern |

Short Pattern |

|||

| 1/2" | 20.5 | 22.8 | 76 | 51 | 3 | 35 |

| 3/4" | 25.9 | 28.1 | 76 | 51 | 3 | 43 |

| 1" | 32.6 | 35.0 | 102 | 51 | 3 | 51 |

| 1 1/4" | 41.4 | 43.6 | 102 | 51 | 5 | 64 |

| 1 1/2" | 47.5 | 49.9 | 102 | 51 | 6 | 74 |

| 2" | 59.5 | 62.4 | 152 | 64 | 8 | 92 |

| 2 1/2" | 72.2 | 75.3 | 152 | 64 | 8 | 105 |

| 3" | 88.1 | 91.3 | 152 | 64 | 10 | 127 |

| 3 1/2" | 100.8 | 104.0 | 152 | 76 | 10 | 140 |

| 4" | 113.5 | 116.7 | 152 | 76 | 11 | 157 |

| 5" | 140.5 | 144.3 | 203 | 76 | 11 | 186 |

| 6" | 167.5 | 171.3 | 203 | 89 | 13 | 216 |

| 8" | 218.3 | 222.1 | 203 | 102 | 13 | 270 |

| 10" | 272.3 | 277.2 | 254 | 127 | 13 | 324 |

| 12" | 323.1 | 328.0 | 254 | 152 | 13 | 381 |

| 14" | 354.8 | 359.9 | 305 | 152 | 13 | 413 |

| 16" | 405.6 | 411.0 | 305 | 152 | 13 | 470 |

| 18" | 456.0 | 462.0 | 305 | 152 | 13 | 533 |

| 20" | 507.0 | 514.0 | 305 | 152 | 13 | 584 |

| 22" | 558.0 | 565.0 | 305 | 152 | 13 | 641 |

| 24" | 609.0 | 616.0 | 305 | 152 | 13 | 692 |

The dimensions are in millimeters

Source : ASME B16.9 - 2007

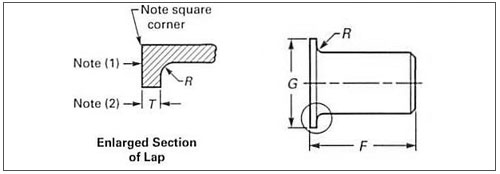

STUB ENDS - Ansi and MSS SP-43 dimensions

STUB ENDS - ANSI B 16.9 and MSS SP-43 dimension |

|||||||

| inches | ND | mm | Diameter of lap | Radius of fillet |

Length F | ||

D |

G | R | R1 | MSS SP43 | ANSI B16.9 | ||

| 1/2 | 15 | 21,34 | 34,92 | 3,17 | 0,80 | 50,80 | 76,20 |

| 3/4 | 20 | 26,67 | 42,86 | 3,17 | 0,80 | 50,80 | 76,20 |

| 1 | 25 | 33,40 | 50,80 | 3,17 | 0,80 | 50,80 | 101,60 |

| 1 1/4 | 32 | 42,16 | 63,50 | 4,76 | 0,80 | 50,80 | 101,60 |

| 1 1/2 | 40 | 48,26 | 73,00 | 6,35 | 0,80 | 50,80 | 101,60 |

| 2 | 50 | 60,32 | 92,10 | 7,93 | 0,80 | 63,50 | 152,40 |

| 2 1/2 | 65 | 73,02 | 104,80 | 7,93 | 0,80 | 63,50 | 152,40 |

| 3 | 80 | 88,90 | 127,00 | 9,52 | 0,80 | 63,50 | 152,40 |

| 3 1/2 | 90 | 101,60 | 139,70 | 9,52 | 0,80 | 76,20 | 152,40 |

| 4 | 100 | 114,30 | 157,20 | 11,11 | 0,80 | 76,20 | 152,40 |

| 5 | 125 | 141,30 | 185,70 | 11,11 | 1,58 | 76,20 | 203,20 |

| 6 | 150 | 168,27 | 215,90 | 12,70 | 1,58 | 88,90 | 203,20 |

| 8 | 200 | 219,07 | 269,80 | 12,70 | 1,58 | 101,60 | 203,20 |

| 10 | 250 | 273,05 | 323,80 | 12,70 | 1,58 | 127,00 | 254,00 |

| 12 | 300 | 323,85 | 381,00 | 12,70 | 1,58 | 152,40 | 254,00 |

| 14 | 350 | 355,60 | 412,70 | 12,70 | 1,58 | 152,40 | 304,80 |

| 16 | 400 | 406,40 | 469,90 | 12,70 | 1,58 | 152,40 | 304,80 |

| 18 | 450 | 457,20 | 533,40 | 12,70 | 1,58 | 152,40 | 304,80 |

| 20 | 500 | 508,00 | 584,20 | 12,70 | 1,58 | 152,40 | 304,80 |

| 22 | 550 | 558,80 | 641,30 | 12,70 | 1,58 | 152,40 | 304,80 |

| 24 | 600 | 609,60 | 692,10 | 12,70 | 1,58 | 152,40 | 304,80 |

| The lap thickness T shall not be less than nominal pipe wall thickness t | |||||||

STUB ENDS - Ansi 16.9 tolerances

DIMENSIONAL TOLERANCES - STUB ENDS |

||||||

| For all fittings | Stub Ends | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Indide Ø at End | Wall Thickness t / t1 |

O.D. of Lap G | Fillet Radius of Lap - R | Overall Length. - F |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | +0 -1 | +0 -1 | 2 |

| 3 a 3 1/2 | 1 | 1,6 | less | +0 -1 | +0 -1 | 2 |

| 4 | +2 -1 | 1,6 | than | +0 -1 | +0 -2 | 2 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | +0 -1 | +0 -2 | 2 |

| 8 | 2 | 1,6 | of nominal | +0 -1 | +0 -2 | 2 |

| 10 | +4 -3 | 3,2 | tickness | +0 -2 | +0 -2 | 2 |

| 12 to 18 | +4 -3 | 3,2 | +0 -2 | +0 -2 | 3 | |

| 20 a 24 | +6 -5 | 4,8 | +0 -2 | +0 -2 | 3 | |

| 26 a 30 | +7 -5 | 4,8 | ||||

| 32 a 48 | +7 -5 | 4,8 | ||||

STUB ENDS - Weights

| NPS inches |

STUB ENDS | |||

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| Approximate weights in kg, density 8 kg/dm3 | ||||